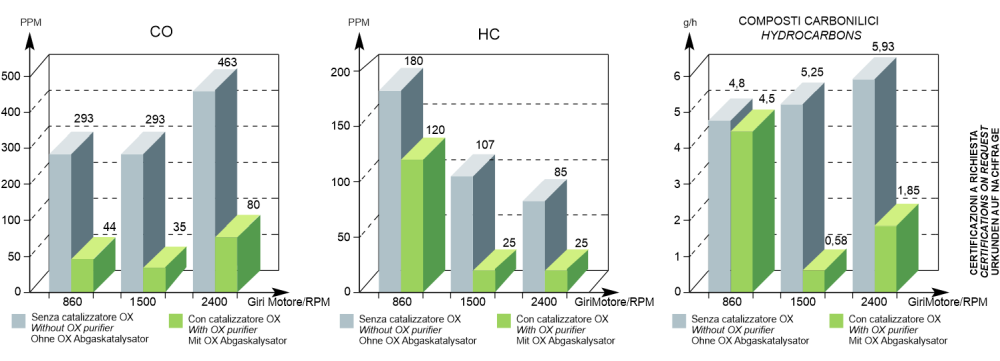

Exhaust gases produdec by internal combustion enzymes employng unleaded petrol, diesel and gas as fuel, contain unburned hydrocarbons, carbon monoxide and aldehydes. When these fumes exit the combustion chamber, they are released into the atmosphere and add significantly to atmospheric pollution.

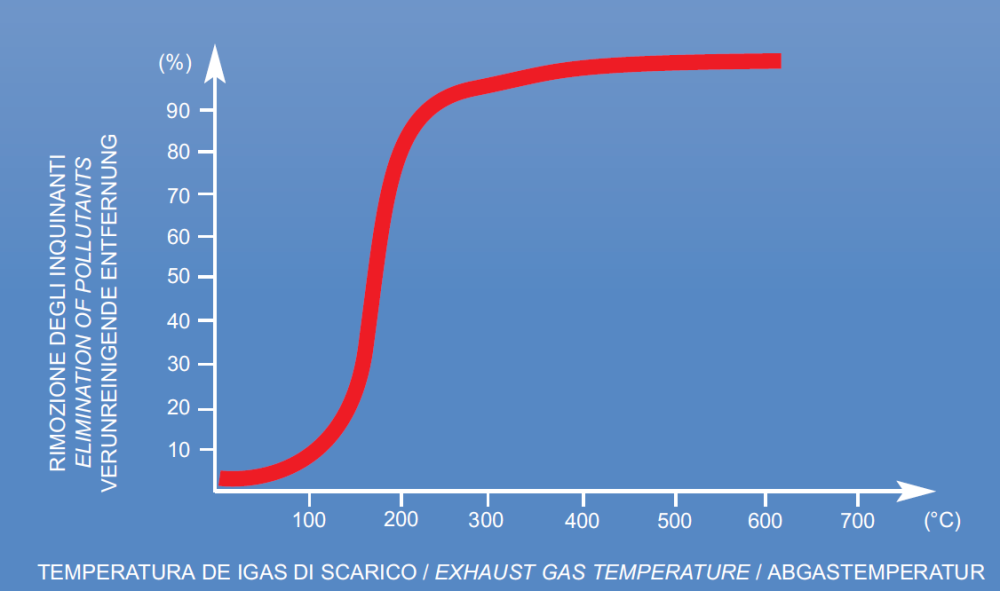

The OX catalytic converter is employed on fork lift trucks, stand-by power generators, earth movers bulldozers, cement mixers, etc. To resolve these problems, the OX catalytic exhaust purifier utilises the chemical conversion performed by catalysis and transforms unburned hydrocarbons (HC), carbon monoxide (CO) and the aldehydes into non-toxic carbon dioxide and water as illustrated by diagram below.

The catalyst is entirely supported on a metallic honeycomb to which optimised amounts of noble metals are employed (platinum, palladium and rhodium). The metallic honeycomb structures offer several advantages

compared to ceramic supports.

- Reduced backpressure since the metallic honeycomb walls are thinner (0,04 mm) as compared with the ceramic version (0,15 mm).

- Smaller overallsize since the reduced internal structure facilitates the use of a reduced catalytic mass.

- In contrast to ceramic honeycomb, metallic honeycomb is far more robust and does not suffer from irreparable fractures or breaks created by impact.

- Metallic honeycomb reaches higher temperatures more quickly than ceramic due to the higher conductivity of metal.

This provides high efficiency even in the event of intermittent use of the unit.

Since the catalyst is isolated with special material including rock wool, ceramic wool and glass wool the catalyst remains efficient even if the engine is idling. Since the OX catalyst does not act as a silencer, is left in place.

The OX purifier is installed as close as possible to the exhaust manifold where the exhaust temperature is highest.

The catalyst becomes operational at 180/200°C and at 250°C, a 90% elimination of pollutants is achieved.

NOTE

With engines employng LPG or PETROL, the exhaust fumes contain insufficient oxigen for efficient catalyst operation. It is therefore essential to install a valve (VK) prior to the catalyst, which introduces a quantity of air in order to ensure sufficient oxygen for efficient combustion.

INSTALLATION

Install the purifier in the exhaust line. There is no particular direction for the exhaust flow through the purifier.

High temperature is essential for high catalytic efficiency.

PRODUCT LIFE

Since the OX purifier employs acatalytic reaction, the life of the catalyst is theoretically unlimited. However, since operating conditions are not ideal; poorly tuned engines, engine vibration and abrasive action offumes to the honeycomb support, all reduce the life of the catalyst. As aresult, the OX purifier requires replacement after approximately 10'000 hours of operation.

MAINTENANCE

The catalyst may be cleaned every 500 hours. This requires dismounting of the purifier

and soaking the catalyst in hot soapy water for 5 hours.

The catalyst may be re-installed after it has dried thoroughly.